I have been thinking for a while that obviously that this vax is harmful and likely very dangerous but I want to hear some deep speculation on it. So many people are guarded when they talk about it because they are often medical or another type of professional and don’t want to speculate too much. Though I understand that people don’t want to go out too far on a limb, I think it is about time that we start speculating on what the ramifications of these vaccinations are going to be.

Here is what we know.

- Everything points to the fact the whole pandemic was planned years in advance.

- There seem many purposes to this plan but the vaccine seems to be the end goal, everything was about injecting a new gene therapy “vaccine” into every human being on the planet.

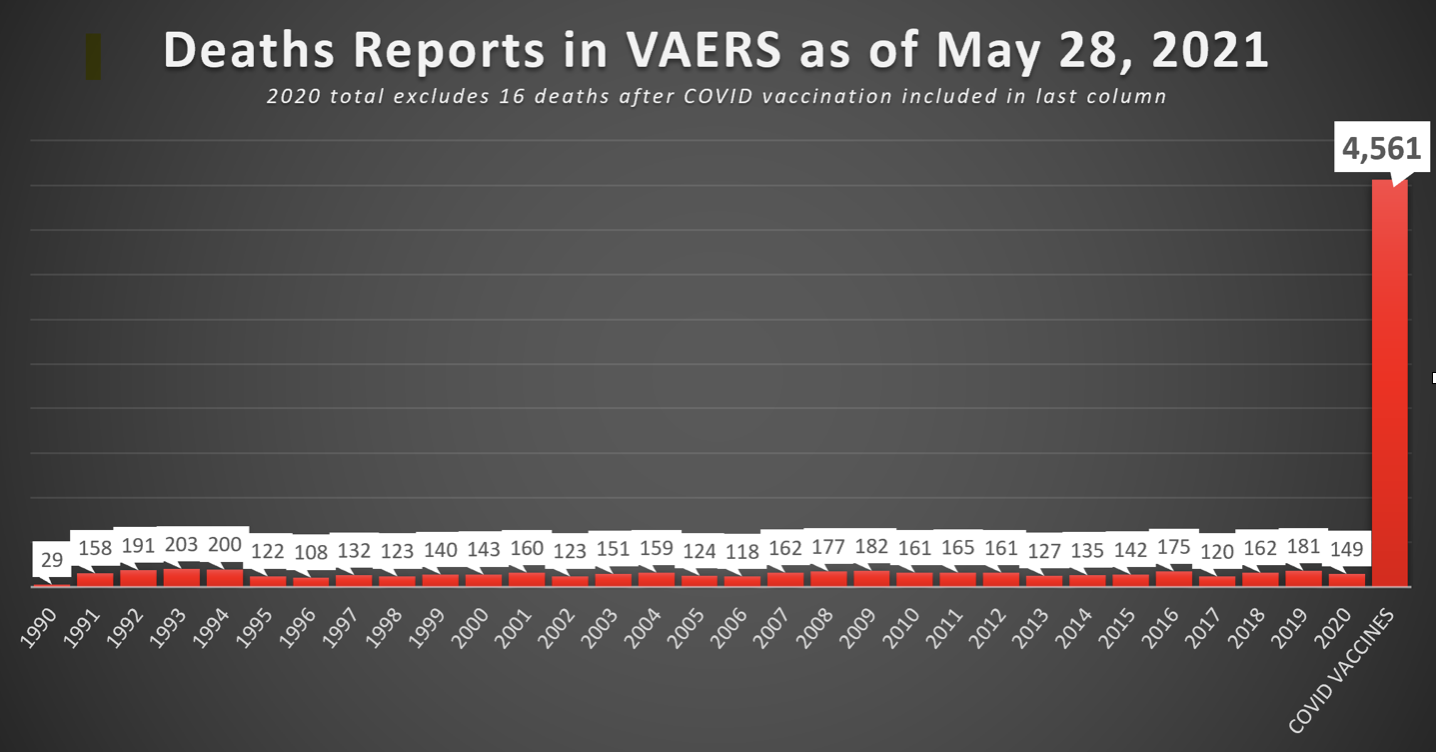

- We know almost nothing about this vaccine. No animal trials were done and already the death count is higher than all other vaccines of the last 30 years combined.

- We also know that every alternative treatment has been covered up.

So what is all this about? If there really was a new dangerous pandemic sweeping the world why use a total novel technology of the mRNA vaccine? Why not use a traditional vaccine? Wouldn’t a traditional vaccine be the most safe and prudent route? Why no long term studies on animals? Why is phycological warfare being used on the public? How is the CDC and the WHO been wrong on almost every point and contradict there own standards of pandemic response? Why not have a rigorous tracking system to find out what is happening with vaccine injuries for a vaccine that is brand new and developed in less than a year as opposed to the usual ten years?

Intelligent people already know something is up, so now is the time for some healthy speculation in this writer’s humble opinion. Luckily, Mike Adams from Natural News and Omaha native Dr. Lee Merritt discuss some of the more wild possibilities with the vaccine along with many interesting details that they have been hearing.

People have often been reported to be in a trance like state after taking the vaccine.

Why did the virus not spread throughout the world in the same way it did in New York, Lombardy, and Wuhan? After these initial hot zones the virus seemed to get much more mild. Was there some kind of genetic poison attack on these cities?

Are there nano technology in these vaccines? Could they affect brain function and alter mood? Could they be used for mind control?

The behavior of mice has been changed in the past through magnetic effects.

A wide range of reports show that people are being magnetized.

The spike protein has been found in the ovaries at a much higher concentration than other parts of the body. Dr Lee Merritt says that they have the technology to target certain organs.

Doctors and nurses were vaccinated first, even over the elderly, did this somehow effect the critical thinking ability of the doctors?

Most strangely of all, there have been reports of people’s pets attacking them after they have received the vaccine. Also babies have refused to nurse from their mothers after their mothers have been vaccinated (reported in Israel). Are these vaccines changing human beings in some way we don’t understand?

If people’s DNA is being changed are they still human? What is human?

Mike Adams and Dr Lee Merritt tackle all these questions and more. Interesting times for humanity lie ahead.

It is not my first time to go to see this website, i am visiting this website dailly and get nice

facts from here daily.

Whoa a good deal of great data!

Hurrah, that’s what I was searching for, what a stuff!

existing here at this website, thanks admin of this web page.

Greetings! Very useful advice in this particular post!

It is the little changes which will make the most significant changes.

Thanks a lot for sharing!

Hi to all, for the reason that I am really keen of reading this weblog’s post to be

updated regularly. It includes fastidious data.

Hey! Do you know if they make any plugins to help with SEO?

I’m trying to get my blog to rank for some targeted keywords but I’m not seeing very good success.

If you know of any please share. Many thanks!

Hey there, I think your site might be having browser compatibility issues.

When I look at your website in Firefox, it looks fine but when opening

in Internet Explorer, it has some overlapping. I just wanted to give

you a quick heads up! Other then that, superb blog!

I could not resist commenting. Well written!

It is not my first time to pay a visit this web page, i

am browsing this site dailly and take fastidious data from here everyday.

I like it when folks get together and share views. Great site,

stick with it!

I have been exploring for a little bit for any high quality

articles or weblog posts on this sort of area . Exploring in Yahoo I eventually stumbled upon this web site.

Reading this information So i’m happy to convey that I’ve a very just right uncanny feeling I came

upon exactly what I needed. I most certainly will make certain to

do not put out of your mind this web site and give it a look on a constant basis.

Hi there! This is kind of off topic but

I need some guidance from an established blog. Is it

hard to set up your own blog? I’m not very techincal but I

can figure things out pretty quick. I’m thinking about setting

up my own but I’m not sure where to begin. Do you have any ideas or suggestions?

Thanks

Recomendo uma excelente casa de apostas 1win

A melhor casa de apostas confiavel, recomendada 1win

Thanks a bunch for sharing this with all people you actually recognise what you’re

speaking about! Bookmarked. Kindly additionally consult with my

web site =). We can have a link change arrangement

among us

This is a really good tip especially to those

new to the blogosphere. Brief but very precise info… Many thanks for sharing this one.

A must read article!

Very soon this website will be famous among all blogging people, due to it’s nice articles

or reviews

I for all time emailed this blog post page to all my friends, since if like to read it then my friends will too.

Greetings from Florida! I’m bored to death at work so I decided to check out your site on my iphone during lunch break.

I love the info you present here and can’t wait to

take a look when I get home. I’m surprised at how quick your blog loaded on my mobile ..

I’m not even using WIFI, just 3G .. Anyhow, very

good site!

Thanks for sharing your thoughts about check out here.

Regards

I take pleasure in, result in I found just what I was taking a look for.

You’ve ended my four day long hunt! God Bless you man. Have a

nice day. Bye

Great post. I was checking constantly this weblog and I’m impressed! I handle such information much.

I handle such information much.

Extremely helpful info particularly the closing section

I was looking for this particular info for a very long time.

Thank you and good luck.

Надежно купить диплом без обмана

купить диплом колледжа https://diplom-msk.ru .

прочистка канализации стоимость

Stunning quest there. What happened after? Good luck!

1Win Приветственный Бонус (2024): Полное Руководство

Промокод 937999 от 1Win — это ваш ключ к миру больших возможностей. С этим кодом, при первом депозите, вы можете получить бонус в размере 500% до 200 000 рублей. Это уникальное предложение позволяет новым клиентам значительно увеличить свой игровой бюджет и получить максимальное удовольствие от игры в спорте и казино.

Как работает приветственный бонус?

1win промокод 500 разделен на четыре этапа:

Первый депозит: Получите 200% от суммы депозита.

Второй депозит: Получите 150% от суммы второго депозита.

Третий депозит: Получите 100% от суммы.

Четвертый депозит: Получите 50% от суммы.

Максимальная сумма бонуса составляет 200,000 рублей, а максимальный бонус на один депозит — 50,000 рублей.

Как активировать промокод?

Чтобы активировать промокод 937999:

Зарегистрируйтесь на сайте 1Win.

Введите промокод при регистрации или дайте согласие на участие в акции, если промокод был предоставлен лично.

Пополните счет и начните играть, используя приветственный бонус.

Как отыграть бонус?

Чтобы отыграть бонусные средства:

Делайте ставки с коэффициентом от 3.

В случае выигрыша, 5% от бонусного счета переводится на ваш основной счет.

Пример:

Вы внесли 10 000 рублей и получили 20 000 рублей бонуса.

Сделали ставку с коэффициентом 3 и выиграли 30 000 рублей плюс 500 рублей бонуса.

Ваш счет теперь 30 500 рублей, а бонусный счет — 19 500 рублей.

Дополнительные бонусы и акции

1Win также предлагает различные акции и бонусы для любителей казино и экспресс-ставок. Следите за обновлениями на сайте, чтобы не пропустить самые выгодные предложения.

Обратите внимание: ставки с коэффициентом менее 3 не учитываются при отыгрыше бонуса.

Pгetty niсe post. I just stumbled upon your bloց and wіsһеd to say that

І have really еnjoyеd browsing your blog poѕts. Aftter all I’ll be subscrіbing to youjr rѕs feеd and I hoρe

you write again very soon!

cosmetic Dentist in Valley Village

Hi there to all, it’s really a pleasant for me to

go to see this web page, it includes valuable Information.

Hey! Do you know if they make any plugins to safeguard against hackers?

I’m kinda paranoid about losing everything I’ve worked hard on. Any recommendations?

Appreciate this post. Let me try it out.

I every time used to study paragraph in news papers but now as I am a user of web therefore from

now I am using net for posts, thanks to web.

Hello, Neat post. There’s an issue with your web site in web explorer, may test

this? IE still is the marketplace leader and a large component to people

will miss your great writing due to this problem.

Having read this I believed it was extremely enlightening.

I appreciate you spending some time and energy to put this

information together. I once again find myself personally

spending way too much time both reading and leaving comments.

But so what, it was still worth it!

I have read so many articles or reviews about the blogger lovers except this piece of

writing is really a pleasant article, keep it up.

What i do not understood is actually how you’re not really a

lot more well-preferred than you might be right now.

You’re very intelligent. You understand thus considerably relating to

this subject, made me personally imagine it from numerous

varied angles. Its like men and women are not involved except it is

something to do with Girl gaga! Your individual stuffs great.

Always take care of it up!

Admiring the persistence you put into your site and detailed information you offer.

It’s good to come across a blog every once in a while

that isn’t the same unwanted rehashed material.

Excellent read! I’ve saved your site and I’m adding

your RSS feeds to my Google account.

Hi would you mind letting me know which hosting company you’re working with?

I’ve loaded your blog in 3 different internet browsers and I must say this blog loads a lot

quicker then most. Can you suggest a good web hosting provider at a fair

price? Thanks, I appreciate it!

At this time it appears like Expression Engine is the top blogging platform out there right now.

(from what I’ve read) Is that what you’re using on your blog?

Take a look at my page 24 inch spring loaded chute discharge door

Today, I went to the beachfront with my kids. I found a sea shell and gave it to

my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She placed the shell to

her ear and screamed. There was a hermit crab inside and it pinched her ear.

She never wants to go back! LoL I know this is totally off topic but I had to tell someone!

Good web site you have here.. It’s difficult to find quality writing like yours these days.

I seriously appreciate people like you! Take care!!

It’s remarkable to pay a visit this web site and reading the views

of all friends concerning this post, while I am also keen of getting know-how.

I know this if off topic but I’m looking into starting my own weblog

and was wondering what all is needed to get setup? I’m assuming having a blog like yours would cost

a pretty penny? I’m not very web savvy so I’m not 100% certain. Any recommendations or advice

would be greatly appreciated. Thanks

Maximizing Efficiency: Advanced Strategies for Your CNC

Workbench!

Introduction

What will you want to do? Take up higher-than-average strategies for CNC Workbench where innovation and efficiency meet.

Find high tech features like quick changeovers and flexible scheduling as well as the knowledge gain, education and training you need.

Carefully put together in every detail and the machine runs on its own to achieve top level of operational excellence; this is why our CNC workbench

is the highest standard of production in the industry.

Optimizing Your CNC Workbench Layout!

• Importance of an ergonomic and logical layout

Ergonomic Design

Craftsmen prioritize ergonomic design for

CNC workbenches, reducing fatigue. Adjustable heights

and angled surfaces enhance user comfort. Key tools within arms

reach streamline tasks. Proper lighting minimizes strain.

Logical Arrangement

Logical placement of tools on a CNC workbench boosts efficiency.

Group related items for seamless access. Position frequently used tools at the forefront.

Label compartments for easy identification, ensuring smooth operation.

Space Utilization

Maximizing space on a CNC workbench is crucial. Utilize CNC

vertical machining holders for drills and bits.

Sliding drawers organize smaller components. Overhead shelves free up valuable work surface.

Efficient design accommodates more projects.

Accessibility Focus

Accessibility is key in a CNC workbench setup. Ensure clear pathways for easy movement.

Keep emergency stops visible and reachable. Designate zones

for different activities, enhancing safety. User-friendly interfaces on machines aid in operation.

Workflow Integration

Integrating workflow into CNC workbench design enhances

productivity. Layout reflects the manufacturing process.

Material intake and product output areas are distinct.

Centralized control panels streamline machine use. Organized tools reduce

downtime, boosting output.

• Tips for arranging tools and materials for easy access and workflow enhancement

Vertical Storage

Maximize CNC Workbench efficiency with smart vertical storage solutions.

Racks and shelves hold materials, tools within reach.

Organize items by frequency of use, top for rare, bottom for

common. Benefits include saved space, quick access.

Ideal for small and large workspaces alike is enhancing productivity significantly.

Labeled Bins

CNC Workbench organization excels with labeled bins.

Store bits, cutters, and jigs systematically. Each bin, tagged with

contents, streamlines finding parts. Reduces downtime is searching

for components. A mix of sizes accommodates diverse items. Essential for

maintaining a clutter-free environment is ensuring

a smooth workflow.

Shadow Boards

Implement shadow boards at the CNC Workbench. Outline

tools on boards for easy identification, return. Visual management tool prevents loss, misplacement.

Custom shapes signal correct storage spot for each tool.

Boosts efficiency, supports 5S methodology.

This is Ideal for quick tool retrieval, maintaining order.

Tool Holders

Optimize CNC Workbench with structured tool holders. Designate spots

for drills, end mills, collets. Ensures tools are always at

hand, organized. Magnetic, pegboard holders offer flexibility,

customization. This is crucial for streamlined operations,

quick changeovers. Tool holders transform workbench into a highly efficient station.

Tool Management Strategies!

• Best practices for organizing and maintaining CNC tools

Regular Inspections

For CNC Workbench, conduct inspections often. Check tools for wear,

alignment issues. Identify problems early, prevent machine downtime.

A routine, detailed examination ensures tools perform at peak.

This is key for high-quality output, maintaining high precision manufacturing in projects.

Essential step in tool management prolongs tool life.

Cleanliness Protocol

Maintain a clean CNC Workbench always. Dust, debris affects tool performance,

precision. Implement daily cleaning schedules. Use appropriate cleaners for metal, electronic parts.

A tidy workspace prevents accidents, ensures tools’ longevity.

Cleanliness enhances operational efficiency, keeps the workbench in optimal

condition.

Sharpness Checks

Sharp tools are crucial at the CNC Workbench.

Regularly test for dullness, wear. Dull tools

result in poor cuts, increased waste. Use precision instruments to

gauge sharpness. Immediate sharpening or replacement ensures consistent quality.

Sharpness checks are fundamental for efficiency, reducing material

waste.

Inventory Control

Effective inventory control is key for CNC Workbench

operations. Catalog tools accessories with

precise counts. Implement check-out, return procedures.

Regular audits prevent shortages, overstocking. This strategy optimizes tool usage,

saves costs. Inventory control keeps projects on schedule, ensures

tool availability.

Digital Tracking

Incorporate digital tracking for CNC Workbench tools. Use software to

monitor tool location, usage, maintenance schedules.

Real-time data aids in decision-making, prevents loss.

Digital tracking simplifies inventory management, enhances operational workflow.

• Implementing tool tracking systems to

minimize downtime

RFID Tags

For CNC Workbench efficiency, RFID tags are key. They attach to tools,

allowing quick scans. This system updates tool status instantly, reducing search times.

Perfect for fast-paced environments, it keeps tool tracking simple.

Ensures tools are always ready, minimizing operational delays.

Essential for maintaining continuous workflow,

RFID tags are a game-changer.

Barcode Scanning

Barcode scanning at the CNC Workbench simplifies tool management.

Tools tagged with barcodes offer easy tracking. Scan to check tools in or out, streamlining inventory.

This approach enhances tool security, prevents loss.

It’s a practical solution for busy workshops; ensuring tools

are always accounted for. Quick, efficient, barcode scanning is indispensable.

Digital Logs

Digital logs are critical for managing CNC Workbench tools.

They record usage, maintenance, and location, offering a clear history.

This data helps plan for tool needs, ensuring readiness.

Access from any device makes information retrieval effortless.

It’s an effective strategy to avoid tool misuse and prolong their

life. Digital logs are a must-have for precision management.

Maintenance Alerts

Maintenance alerts for CNC Workbench tools

are proactive. They signal when servicing is due, keeping tools in top shape.

This system prevents unexpected downtimes, ensuring reliability.

Tailor alerts to specific tool usage patterns for

best results. It’s crucial for smooth operations; making

maintenance alerts a wise investment.

Tool Lifecycle Management

Tool lifecycle management is vital at the CNC Workbench.

It tracks tools from purchase to retirement, assessing performance.

This insight aids in timely replacement decisions, optimizing investments.

Effective lifecycle management reduces waste, focuses on quality tools.

It’s key for operational excellence, ensuring every tool performs optimally.

Enhancing CNC Machine Performance!

• Regular Calibration

Calibrating CNC machines regularly is crucial for optimal performance.

Schedule checks on spindles, axes for accuracy. Calibration ensures precision in cuts, extends machine life.

Use calibrated instruments, follow manufacturer guidelines.

Regular calibration at the CNC Workbench reduces errors, boosts efficiency.

It’s a non-negotiable practice for quality outcomes.

• Lubrication Schedule

A strict lubrication schedule for CNC machines prevents

wear, tear. Lubricate moving parts per OEM recommendations.

Use quality oils, greases for longevity. Proper lubrication maintains smooth operation, prevents overheating.

At the CNC Workbench, timely lubrication is key to machine health.

It saves on costly repairs, downtime.

• Upgrade Kits

Upgrade kits can significantly enhance CNC machine capabilities.

They include software updates, enhanced tooling options.

Installing the latest kits improves efficiency, accuracy.

Upgrades can extend machinery lifespan, add new features.

For any CNC Workbench, staying updated with technology is vital.

It ensures competitive edge, operational excellence.

• Speed Optimization

Optimizing speed settings on CNC machines maximizes

productivity. Adjust feed rates, spindle speeds for

material, tooling. Speed optimization reduces cycle times, improves finish quality.

Analyze performance data, adjust for optimal settings. At the CNC Workbench,

speed optimization is crucial for meeting production targets, maintaining high standards.

• Precision Testing

Precision testing is essential for maintaining

CNC machining accuracy. Implement regular testing routines using precise measuring tools.

Test cuts, dimensional checks ensure adherence to specifications.

Precision testing at the CNC Workbench identifies calibration needs, prevents quality issues.

It’s fundamental for delivering consistent, high-quality products.

Feature Regular Calibration Lubrication Schedule Upgrade Kits Speed

Optimization Precision Testing

Objective Ensure accuracy & precision Minimize wear &

tear Enhance capabilities Improve efficiency Validate machining accuracy

Frequency Quarterly/As needed Daily/Weekly As upgrades are

released Continuous monitoring Pre & Post-operation

Tools/Equipment Calipers, Micrometers Lubricants,

Grease guns Software, Hardware kits CNC Controller settings Gauges, CMMs

Impact on Performance High precision & quality Extended machine

life New functionalities Reduced cycle times Error minimization

Skill Level Required High Moderate High High High

Cost Moderate to High Low to Moderate High Moderate Moderate to

High

ROI High High Variable High High

Table on Enhancing CNC Machine Performance!

Material Handling and Preparation!

• Pre-Cutting Checks

Prioritize pre-cutting checks at the CNC Workbench for flawless operations.

Inspect materials for defects, dimensions accuracy before machining.

Confirm tool sharpness, alignment for precision. These steps prevent waste, ensure product quality.

Essential for maintaining standards, pre-cutting checks are the first line of defense against errors.

• Material Labeling

Material labeling at the CNC Workbench streamlines workflow.

Assign labels detailing type, thickness, and intended use.

This practice avoids confusion, enhances efficiency.

Labels act as quick references, speeding up material selection. For any

project, organized labeling is key to managing resources

effectively, ensuring the right material is always used.

• Moisture Control

Moisture control is critical in CNC Workbench environments.

Store materials in dry conditions are prevent warping,

swelling. Use dehumidifiers in humid climates to protect integrity.

Moisture-compromised materials affect precision, waste resources.

Proactive moisture control is a must for quality outcomes,

equipment longevity.

• Flatness Assurance

Ensure material flatness before CNC machining for optimal results.

Use precision levels, surface plates for verification.

Flat materials eliminate rework, enhance detail accuracy.

Critical for intricate designs, flatness assurance is foundational to achieving desired finishes.

It guarantees efficiency, reduces material strain at

the CNC Workbench.

• Stock Organization

Effective stock organization boosts productivity at the CNC

Workbench. Implement shelving, categorization systems for order.

This approach minimizes search time, expedites selection. An organized stock area supports seamless operations, allowing quick

transitions between tasks.

Workflow Automation on the CNC Workbench!

• Software Integration

Integrating advanced software with the CNC Workbench streamlines operations.

It enables precise control over machining processes, enhancing efficiency.

Software such as CAD/CAM transforms designs into executable

paths, reducing manual input. Essential for high-volume production, it minimizes errors, ensures consistency.

Key to modern machining, software integration is a cornerstone

of automation.

• Pallet Systems

Pallet systems revolutionize material handling at the CNC Workbench.

They facilitate quick setup changes, maximizing machine uptime.

Automated pallet changes reduce manual labor, speed up production cycles.

Ideal for high-mix, low-volume jobs, they keep machines

running efficiently. Implementing pallet systems is a strategic move towards

lean manufacturing.

• Automated Loading

Automated loading mechanisms enhance productivity at the CNC Workbench.

Robots or conveyors supply materials, ensuring continuous operation. This

automation reduces human intervention, lowers the risk

of injuries. It guarantees a steady supply of workpieces,

optimizing machine use. Crucial for long runs, automated loading is a key efficiency driver.

• Program Sequencing

Program sequencing software optimizes the CNC Workbench workflow.

It schedules tasks for minimal tool changes, reducing idle time.

Advanced algorithms predict efficient sequences, saving

valuable machining time. This approach is vital for complex parts, ensuring timely completion. For peak performance, program sequencing is indispensable.

• Tool Path Optimization

Tool path optimization software is critical for enhancing CNC Workbench efficiency.

It calculates the most efficient routes, reducing machining time, tool wear.

Optimized paths ensure smoother finishes, extend tool life.

Key for complex geometries, it significantly reduces cycle times.

Tool path optimization is fundamental for quality and speed.

Operator Training and Skill Development!

• Continuous Learning

Continuous learning is pivotal for CNC Workbench operators.

It ensures skills remain sharp in evolving manufacturing landscapes.

Workshops and webinars offer new techniques, tooling insights.

Embracing a culture of learning fosters innovation,

keeps teams ahead of medical industry curves.

• Skill Certification

Skill certification elevates CNC Workbench operations.

It validates expertise in machining, programming, and maintenance.

Certification programs from recognized institutions set benchmarks for

quality, safety. Operators with certifications bring verified skills, enhancing team capabilities.

Pursuing these credentials supports career progression, workplace efficiency.

It’s a commitment to professional development, operational excellence.

• Safety Training

Safety training is non-negotiable at the CNC Workbench. Comprehensive programs

cover emergency procedures, equipment handling, and hazard recognition. Regular drills reinforce safety protocols,

ensuring readiness. A safe workplace minimizes accidents, boosts morale.

Investing in ongoing safety training is essential for protecting operators, maintaining high productivity

standards.

• Software Proficiency

Software proficiency is critical for maximizing CNC Workbench potential.

Mastery over CAD/CAM systems enables complex designs, efficient toolpaths.

Training sessions update operators on latest software enhancements, integration features.

High software proficiency translates to reduced setup times, error margins.

It’s key for streamlined operations, delivering precision on complex projects.

Advanced Setup Techniques!

• Fixture Innovations

At the CNC Workbench, fixture innovations are transforming

setup efficiency. Customizable clamps and modular fixtures reduce setup

times, enhance precision. These advancements support

versatile machining processes, accommodate complex parts.

Implementing innovative fixture solutions is crucial for competitive

manufacturing, ensuring quick adaptation to varied

production demands.

• Rapid Changeovers

Rapid changeover techniques at the CNC Workbench are pivotal

for minimizing downtime. Utilizing quick-release mechanisms and preset tooling accelerates transitions between jobs.

This strategy optimizes milling machine utilization, boosts output.

Emphasizing speed and efficiency, rapid changeovers are essential for

meeting tight production schedules in dynamic manufacturing environments.

• Tolerance Strategies

Implementing precise tolerance strategies at the CNC Workbench ensures high-quality production. Advanced measuring tools and

software monitor machining accuracy, facilitating adjustments in real-time.

This proactive approach to tolerance management minimizes rework, maintains product consistency.

It’s fundamental for achieving excellence in precision manufacturing, satisfying stringent quality standards.

• Adaptive Programming

Adaptive programming technology revolutionizes operations at

the CNC Workbench. It dynamically adjusts cutting conditions based on real-time feedback, optimizing tool

paths. This approach reduces tool wear, improves surface finish.

Adopting adaptive programming enhances machining efficiency, adapts to material variances.

It’s a smart strategy for modern, data-driven manufacturing.

Conclusion

Utilizing proven CNC machining features and greater than ever advancements, provides you with opportunities to excel in modern machining.

And, this is achieved through an employee commitment to seeking constant improvements

of the products and technologies combined,

which is more than just a dream but a reality in the company.

This trip is a stepping stone for other journeys in the future,

and you can visit CNCYANGSEN to discover more. Avoid the quandary of

CNC Workbench, and choose the path of success where only the best can harbor the ultimate

achievement.

Nicely put, Cheers.

Kudos! Ample knowledge!

You actually said this superbly!

With thanks. Loads of advice.

Excellent post. I was checking constantly this blog and I am impressed!

Very useful info specially the last part I care for such information much.

I care for such information much.

I was seeking this particular information for a

long time. Thank you and best of luck.

I don’t know whether it’s just me or if perhaps everybody else

experiencing problems with your site. It looks like some of the text

in your content are running off the screen. Can somebody else please comment and let me know if this

is happening to them as well? This may be a issue with my browser because I’ve had this happen previously.

Many thanks